We use cookies and analytics to help improve the quality of the services we offer and analyse how our website is used. No personal data is collected.

Please read our Cookie Policy here.

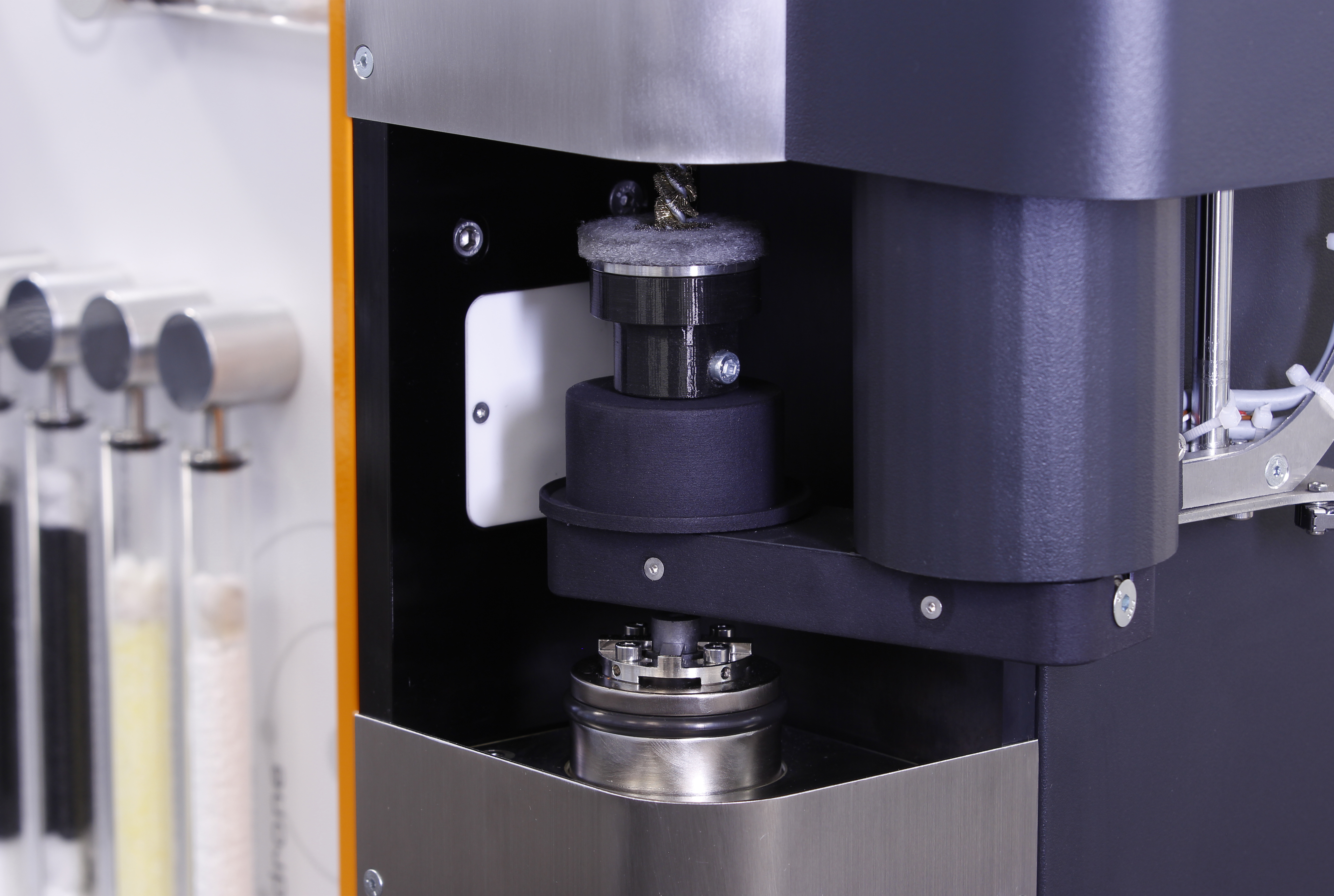

The new ELEMENTRAC ONH-p 2 is a powerful and robust elemental analyzer for measurement of oxygen, nitrogen and hydrogen concentrations in inorganic materials like steel, iron, copper or ceramics. The highly sensitive NDIR and thermal conductivity detectors reliably detect element concentrations from low ppm content to high percentages.

The innovative sample port system with pulsed ch amber rinsing and vertical sample drop allow for user-friendly and comfortable analysis of rod-shaped, granular or powdery samples with a weight of up to 2 grams.

amber rinsing and vertical sample drop allow for user-friendly and comfortable analysis of rod-shaped, granular or powdery samples with a weight of up to 2 grams.

The ELEMENTRAC ONH-p 2 elemental analyzer is available as a single-element analyzer for oxygen, nitrogen or hydrogen only, or in a multi-element configuration for measuring ON, OH, NH, or ONH. Whereas oxygen is determined as CO2 in up to two infrared cells, nitrogen and hydrogen are detected in their elemental form in a thermal conductivity cell. The ELEMENTRAC ONH-p 2 elemental analyzer uses an ON mode with helium carrier gas (optionally argon) and an OH mode with nitrogen carrier gas to take advantage of the sensitive thermal conductivity cell.

The chemicals and filters required for the operation of the ELEMENTRAC ONH-p 2 elemental analyzer are arranged conveniently on the front panel and can be concealed behind a removable door during routine operation. This arrangement significantly reduces the time required for maintenance and increases user-friendliness. In addition, innovative details considerably improve the reproducibility of measurements.

The ELEMENTRAC ONH-p 2 elemental analyzer meets or exceeds the requirements of all relevant international standards such as ASTM E 1019 or DIN EN 3976.

Typical sample materials: alloys, aluminum, ashes, carbides, cast iron, copper, ferroalloys, iron, metals, ores, refractory metals, silicon, steel, etc.

alloys, aluminum, ashes, carbides, cast iron, copper, ferroalloys, iron, metals, ores, refractory metals, silicon, steel

silicon, steel

• Low gas consumption and high sensitivity due to closed gas system

• Easy application of pins, powders, and granules

• Inexpensive argon as carrier gas possible

• Short analysis time

• Powerful impulse furance with 8.5kW

• Optional Autocleaner

• Reliable ONH elemental analysis of inorganic samples like steel, non-ferrous metals, ceramics, slags, ores, etc.

| Measured elements | hydrogen, nitrogen, oxygen |

| Samples | inorganic |

| Furnace alignment | vertical |

| Sample carrier | graphite crucibles |

| Field of application | ceramics, engineering / electronics, steel / metallurgy |

| Furnace | electrode impulse furnace (max. 8,5 KW*), temperatures in excess of 3,000 °C |

| Detection method | solid state infrared absorption for oxygen thermal conductivity for nitrogen and hydrogen |

| Typical analysis time | 120 - 180 s |

| Chemicals required | Schuetze reagents, copper oxide, magnesium perchlorate, sodium hydroxide |

| Gas required | compressed air, helium 99.995 % pure, nitrogen 99.995% pure, argon 99.995% pure (if required), all gases with (2 - 4 bar / 30 - 60 psi) |

| Power requirements | 3~ 400 V, 50/60 Hz, max. 8,500 W |

| Dimensions (W x H x D) | 56 x 78 x 64 cm |

| Weight | ~165 kg |

| Required equipment | PC, balance (resolution 0.0001g), monitor |